개요

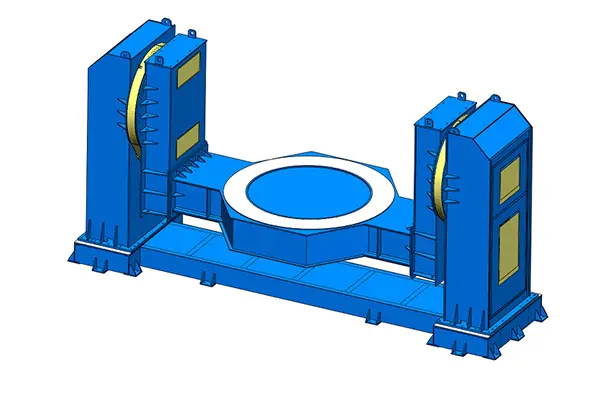

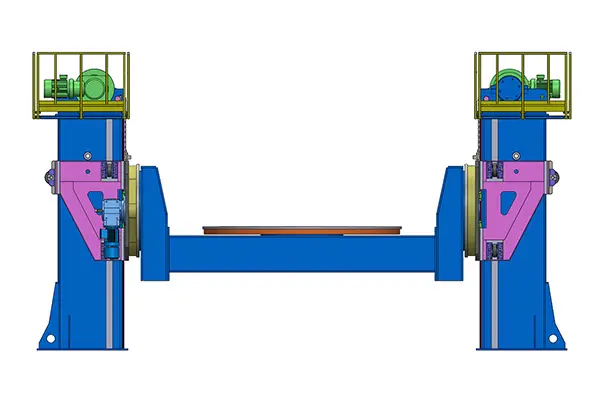

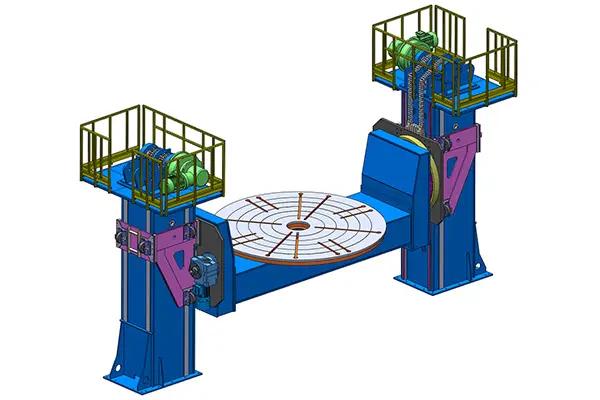

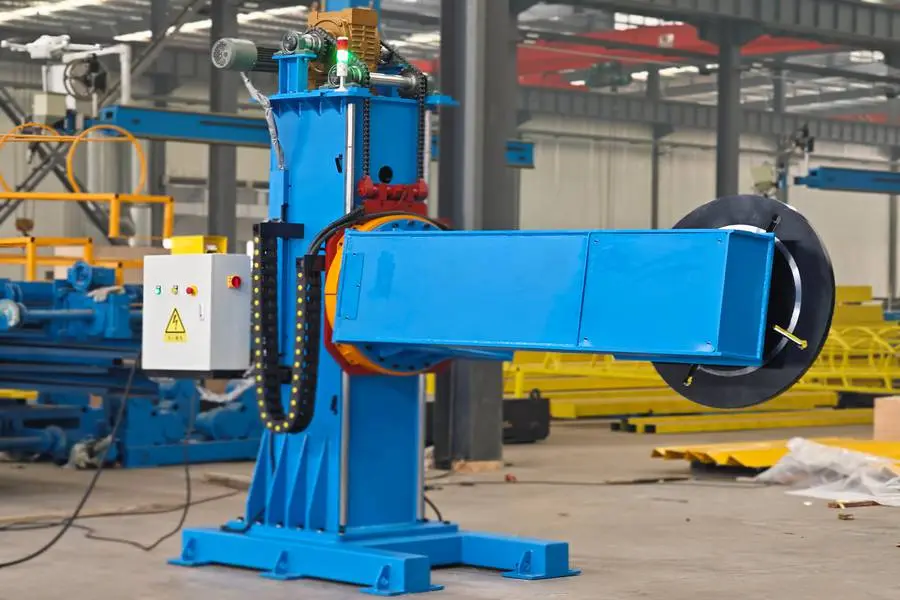

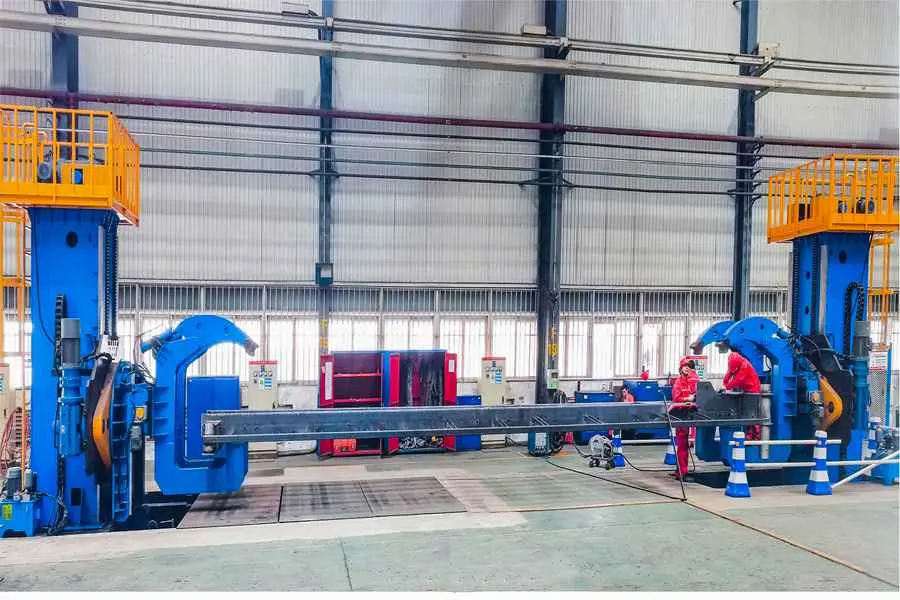

The Bota Head & Tailstock Series provides the ideal solution for welding long structures such as trailer chassis, railway cars, and excavator booms. Unlike single-column positioners, this dual-support configuration secures the workpiece at both ends, effectively eliminating bending or torque distortion caused by gravity. The Tailstock can be mounted on rails to accommodate variable workpiece lengths, offering maximum flexibility for your production line.

특징

| 모델 | BHBS50 | BHBS100 | BHBS200 | BHBS300 | BHBS500 | BHBS1000 | BHBS2000 |

|---|---|---|---|---|---|---|---|

| 적재 한도(kg) | 5000 | 10000 | 20000 | 30000 | 50000 | 100000 | 200000 |

| 회전 속도(rpm) | 0.05-0.5 | 0.05-0.5 | 0.04-0.4 | 0.03-0.3 | 0.02-0.2 | 0.01-0.1 | 0.01-0.1 |

| 플립 속도(rpm) | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| 플립 각도(°) | 0±90 | 0±90 | 0±90 | 0±90 | 0±90 | 0±90 | 0±90 |

| 테이블 직경(mm) | ⌀2000 | ⌀2000 | ⌀2500 | ⌀3000 | ⌀4000 | ⌀5000 | ⌀5000 |

| 로터리 모터 출력(kw) | 3 | 4 | 5.5 | 7.5 | 11 | 18.5 | 22 |

| 틸팅 모터 출력(kw) | 2×2.2 | 2×3 | 2×5.5 | 2×7.5 | 2×11 | 2×18.5 | 2×22 |

| 최대 편심(mm) | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| 최대 무게 중심 거리(mm) | 600 | 600 | 1000 | 1500 | 2000 | 2500 | 2500 |

| 속도 모드 | AC 주파수 변환기 무단 속도 조정 | AC 주파수 변환기 무단 속도 조정 | AC 주파수 변환기 무단 속도 조정 | AC 주파수 변환기 무단 속도 조정 | AC 주파수 변환기 무단 속도 조정 | AC 주파수 변환기 무단 속도 조정 | AC 주파수 변환기 무단 속도 조정 |

지능형 용접을 위한 설계

Eliminate Structural Distortion

When welding long, heavy frameworks—such as truck chassis or architectural beams—on a standard single-column positioner, the “cantilever effect” often causes the workpiece to sag or twist under its own weight. This physical distortion compromises geometric accuracy and leads to misaligned weld seams. Bota solves this by supporting your workpiece from both ends. Our synchronized headstock and tailstock system effectively neutralizes gravity, creating a rigid, stable axis of rotation. This ensures the part remains perfectly straight throughout the 360° welding process, eliminating the need for costly post-weld straightening and guaranteeing consistent structural integrity.

지능형 용접을 위한 설계

Adapt to Variable Lengths

In heavy fabrication, project requirements change rapidly. A fixed-length setup limits your workshop’s capability. Bota empowers your production with a movable tailstock mounted on precision floor rails. This design allows operators to easily slide and lock the unit to accommodate a vast range of workpiece lengths—from short hoppers to extra-long trailer frames. By transforming a single equipment setup into a versatile welding station, we help you maximize equipment utilization and Return on Investment (ROI), significantly reducing changeover time between different product batches without the need for multiple specialized fixtures.

글로벌 고객 쇼케이스

전 세계 여러 국가와 지역에서 고품질의 용접 장비를 제공하며 다양한 산업 분야의 고객에게 맞춤형 솔루션을 성공적으로 제공해 왔습니다. 당사의 고객은 자동차 제조, 건설, 조선, 항공우주 등 다양한 분야에 걸쳐 있습니다.

글로벌 고객의 신뢰

지금 견적 요청하기

간단한 견적 요청을 제출하면 프로젝트에 맞는 구매 추천과 가격을 빠르게 받아볼 수 있습니다.