Overview

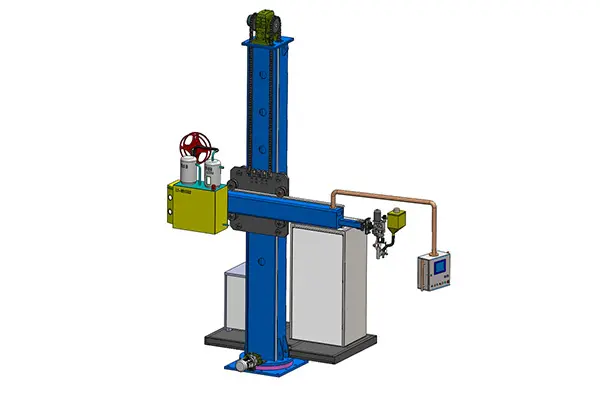

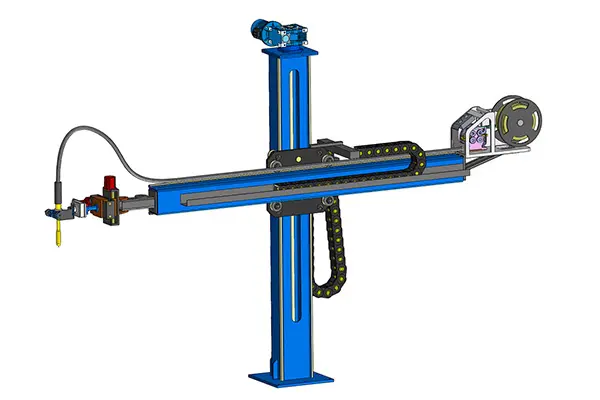

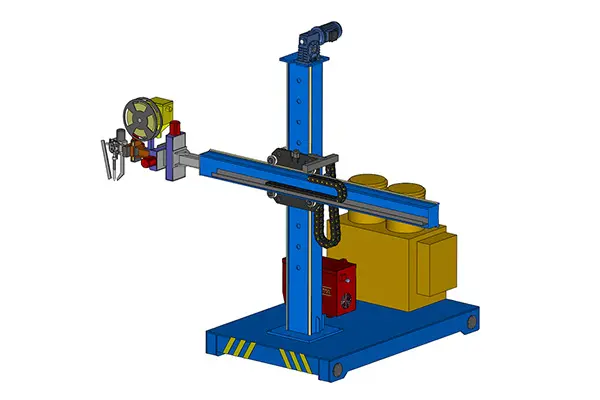

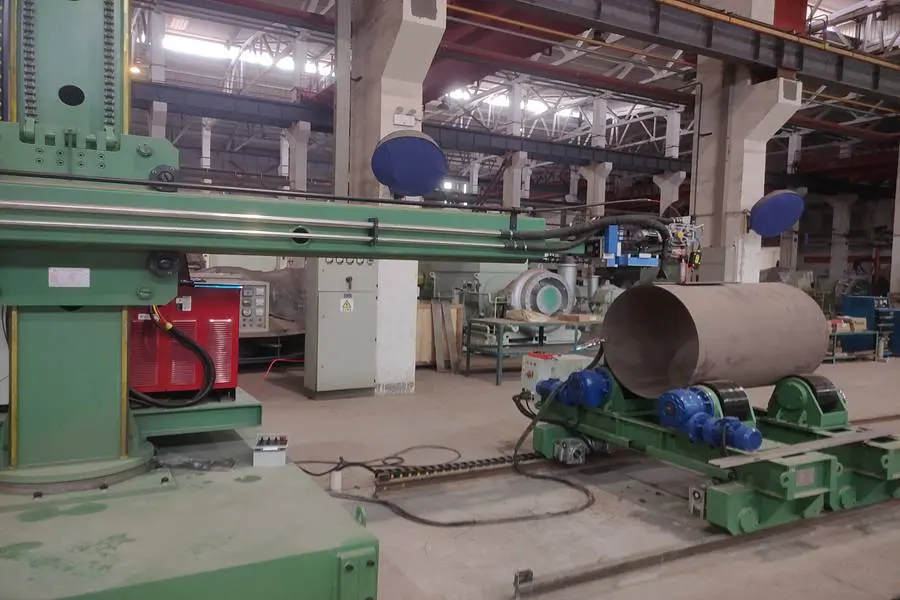

The standard welding manipulator is ideal for medium-load and general welding tasks, widely used in industries such as pressure vessels, pipelines, and steel structures. Compared to heavy-duty manipulators, it is more compact and cost-effective; compared to man-riding types, it offers fully automated control without the need for manual tracking, ensuring safer and more efficient operation. It’s a practical choice for companies seeking stable and efficient production.

Features

| Model Parameter | BCZQ1.5*1.5 | BCZQ2*2 | BCZQ3*3 | BCZQ4*4—4*5 |

|---|---|---|---|---|

| Effective lifting range(mm) | 1500 | 2000 | 3000 | 4000 |

| Effective retracting range (mm) | 1500 | 2000 | 3000 | 4000—5000 |

| Lifting speed(mm/min) | 1000 | 1000 | 1000 | 1000 |

| Retracting speed (mm/min) | 100-1000 | 100-1000 | 100-1000 | 100-1000 |

| Min.boom height(mm) | 700-800 | 700-800 | 700-800 | 700-800 |

| Max permissible load at boom end (kg) | 80-120 | 80-120 | 80-120 | 80-120 |

| Column rotation | Manual/Motorized | Manual/Motorized | Manual/Motorized | Manual/Motorized |

| Trolley travelling (mm/min) | Manual/Motorized | Manual/Motorized | Manual/Motorized | Manual/Motorized |

| Inner span of trolley rail (mm) | 1000-2500 | 1000-2500 | 1000-2500 | 1000-2500 |

Designed for Intelligent Welding

Precision Linear Motion Control

Replacing manual torch holding with our automated manipulator guarantees consistent travel speed and arc length. This precise linear accuracy is essential for MIG/MAG and TIG processes, ensuring uniform bead appearance and eliminating defects caused by operator hand fatigue.

Designed for Intelligent Welding

Seamless System Integration

Designed as the versatile core of a welding center, the standard series integrates easily with Bota Welding Rotators or Positioners. This allows small-to-medium fabrication shops to upgrade to fully automated circumferential welding without the massive investment of heavy-duty custom systems.

Optional Accessories

Global Client Showcase

In multiple countries and regions around the world, we provide high-quality welding equipment and have successfully offered customized solutions to clients across various industries. Our customers span multiple sectors, including automotive manufacturing, construction, shipbuilding, aerospace, and more.

Trusted by Global Clients

Request a Quote Now

By submitting a simple quote request, you can quickly receive purchasing recommendations and pricing tailored to your project.