Overview

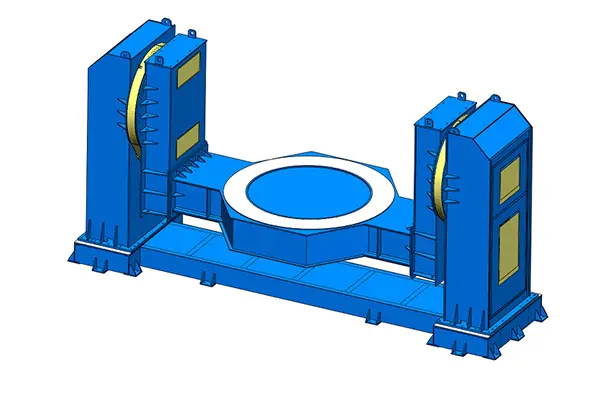

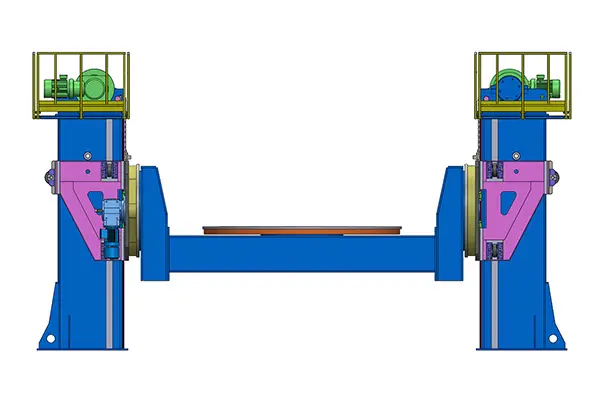

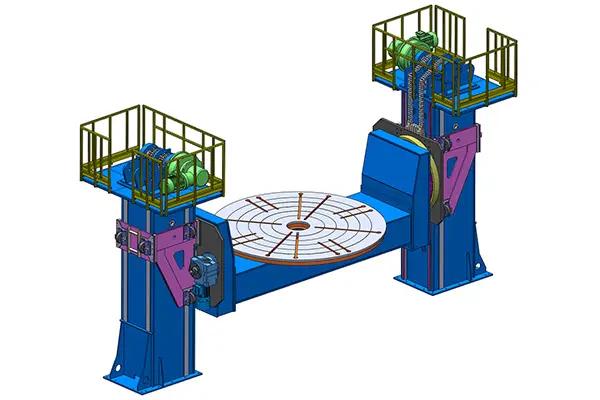

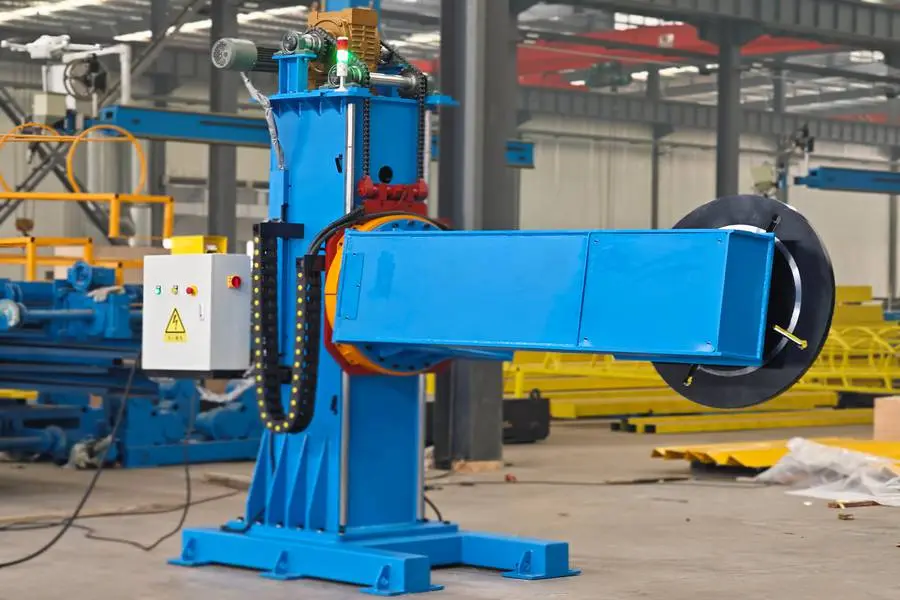

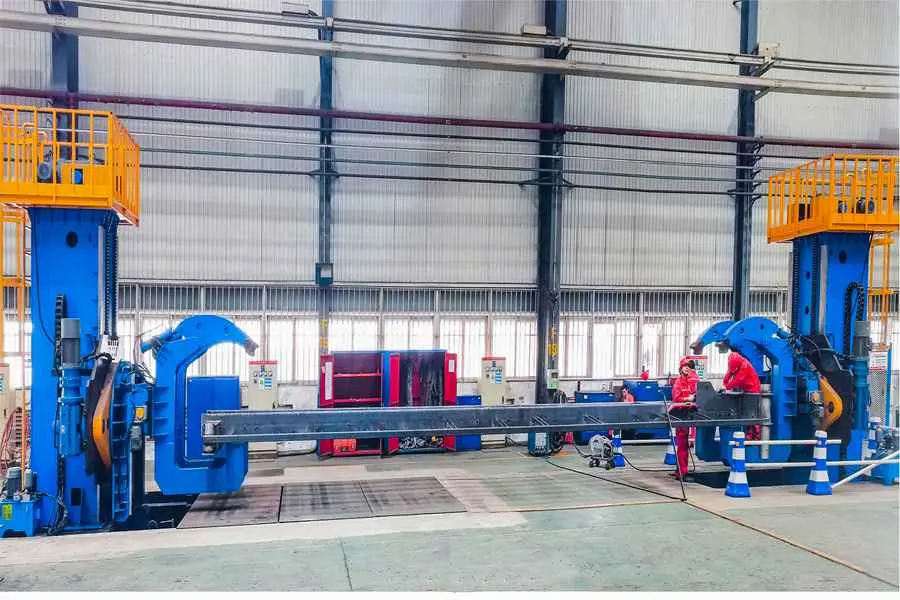

The Bota Head & Tailstock Series provides the ideal solution for welding long structures such as trailer chassis, railway cars, and excavator booms. Unlike single-column positioners, this dual-support configuration secures the workpiece at both ends, effectively eliminating bending or torque distortion caused by gravity. The Tailstock can be mounted on rails to accommodate variable workpiece lengths, offering maximum flexibility for your production line.

Features

| Modle | BHBS50 | BHBS100 | BHBS200 | BHBS300 | BHBS500 | BHBS1000 | BHBS2000 |

|---|---|---|---|---|---|---|---|

| Load cap(kg) | 5000 | 10000 | 20000 | 30000 | 50000 | 100000 | 200000 |

| Rotation speed (rpm) | 0.05-0.5 | 0.05-0.5 | 0.04-0.4 | 0.03-0.3 | 0.02-0.2 | 0.01-0.1 | 0.01-0.1 |

| Flip speed(rpm) | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Flip angle(°) | 0±90 | 0±90 | 0±90 | 0±90 | 0±90 | 0±90 | 0±90 |

| Table diameter(mm) | ⌀2000 | ⌀2000 | ⌀2500 | ⌀3000 | ⌀4000 | ⌀5000 | ⌀5000 |

| Rotary motor power (kw) | 3 | 4 | 5.5 | 7.5 | 11 | 18.5 | 22 |

| Tilting motor power (kw) | 2×2.2 | 2×3 | 2×5.5 | 2×7.5 | 2×11 | 2×18.5 | 2×22 |

| Max.eccenticity (mm) | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Max Gravity Center Distance (mm) | 600 | 600 | 1000 | 1500 | 2000 | 2500 | 2500 |

| Speed mode | AC frequeney converter stepless speed adjustment | AC frequeney converter stepless speed adjustment | AC frequeney converter stepless speed adjustment | AC frequeney converter stepless speed adjustment | AC frequeney converter stepless speed adjustment | AC frequeney converter stepless speed adjustment | AC frequeney converter stepless speed adjustment |

Designed for Intelligent Welding

Eliminate Structural Distortion

When welding long, heavy frameworks—such as truck chassis or architectural beams—on a standard single-column positioner, the “cantilever effect” often causes the workpiece to sag or twist under its own weight. This physical distortion compromises geometric accuracy and leads to misaligned weld seams. Bota solves this by supporting your workpiece from both ends. Our synchronized headstock and tailstock system effectively neutralizes gravity, creating a rigid, stable axis of rotation. This ensures the part remains perfectly straight throughout the 360° welding process, eliminating the need for costly post-weld straightening and guaranteeing consistent structural integrity.

Designed for Intelligent Welding

Adapt to Variable Lengths

In heavy fabrication, project requirements change rapidly. A fixed-length setup limits your workshop’s capability. Bota empowers your production with a movable tailstock mounted on precision floor rails. This design allows operators to easily slide and lock the unit to accommodate a vast range of workpiece lengths—from short hoppers to extra-long trailer frames. By transforming a single equipment setup into a versatile welding station, we help you maximize equipment utilization and Return on Investment (ROI), significantly reducing changeover time between different product batches without the need for multiple specialized fixtures.

Global Client Showcase

In multiple countries and regions around the world, we provide high-quality welding equipment and have successfully offered customized solutions to clients across various industries. Our customers span multiple sectors, including automotive manufacturing, construction, shipbuilding, aerospace, and more.

Trusted by Global Clients

Request a Quote Now

By submitting a simple quote request, you can quickly receive purchasing recommendations and pricing tailored to your project.