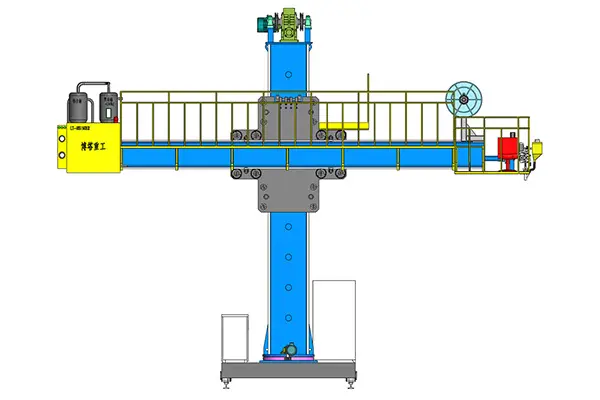

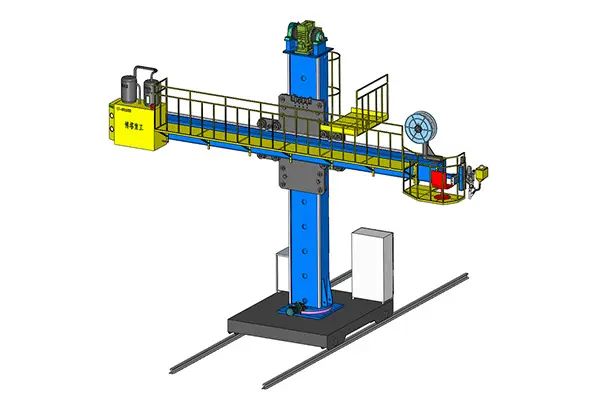

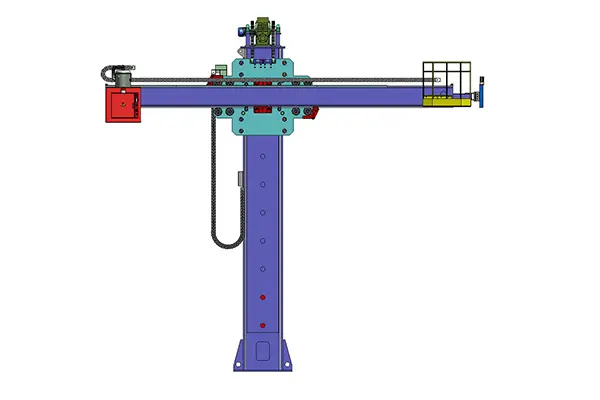

Overview

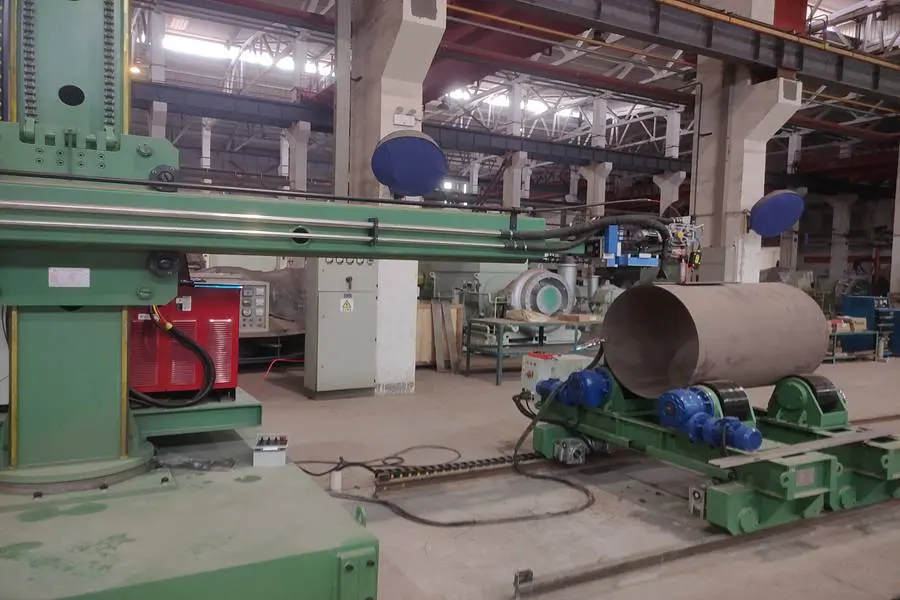

This equipment is specially designed for automatic welding of large cylindrical or structural components, offering high precision and efficiency. The stable column structure, along with a boom that moves vertically and horizontally, allows for accurate torch positioning. It features a comfortable operator seat and a control platform, enabling real-time monitoring and control during welding. Ideal for industries such as pressure vessel, boiler, and pipeline manufacturing, it improves weld quality and reduces labor intensity. Various sizes and travel mechanisms are available upon request, with compatibility for SAW, MIG/MAG, and TIG welding systems.

Features

| Modle | BCZR4*4-5*5 | BCZR6*6 | BCZR7*7 | BCZR8*8—14*14 |

|---|---|---|---|---|

| Effective lifting range(mm) | 4000—5000 | 6000 | 7000 | 8000—14000 |

| Effective retracting range (mm) | 4000—5000 | 6000 | 7000 | 8000—14000 |

| Lifting speed(mm/min) | 1000 | 1000 | 1000 | 1000 |

| Retracting Speed (mm/min) | 100-1000 | 100-1000 | 100-1000 | 100-1000 |

| Min.boom height (mm) | 1200-1300 | 1200-1300 | 1200-1300 | 1200-1300 |

| Max permissible load at boom end (kg) | 500 | 500 | 500 | 500 |

| Column rotation Angle(°) | ±180° | ±180° | ±180° | ±180° |

| Column rotation Speed (pm) | O.17rpm/or Manual rotation | O.17rpm/or Manual rotation | O.17rpm/or Manual rotation | O.17rpm/or Manual rotation |

| Trolley travelling(mm/min) | 2000 | 2000 | 2000 | 2000 |

| Inner span of trolley rail(mm) | 2000-3000 | 2000-3000 | 2000-3000 | 2000-3000 |

Designed for Intelligent Welding

Direct Visual Control at the Boom Tip

While cameras are useful, critical heavy-wall welding often requires the experienced eye of a master welder. Our Manned Platform allows the operator to sit safely right next to the welding head, regardless of the height. This ensures they can spot and correct subtle arc variations or flux issues instantly, guaranteeing a defect-free weld that remote monitoring simply cannot match.

Designed for Intelligent Welding

Real-Time Parameter Adjustment

Advanced processes like Electroslag Strip Cladding or Multi-wire SAW require constant fine-tuning of current, voltage, and travel speed during the weld. Our operator walkway platform is a fully equipped “flying workstation” with all control panels within arm’s reach. This allows the welder to adjust parameters “on-the-fly” without stopping the machine, preventing start-stop defects and ensuring a perfect overlay surface.

Optional Accessories

Global Client Showcase

In multiple countries and regions around the world, we provide high-quality welding equipment and have successfully offered customized solutions to clients across various industries. Our customers span multiple sectors, including automotive manufacturing, construction, shipbuilding, aerospace, and more.

Trusted by Global Clients

Request a Quote Now

By submitting a simple quote request, you can quickly receive purchasing recommendations and pricing tailored to your project.