Overview

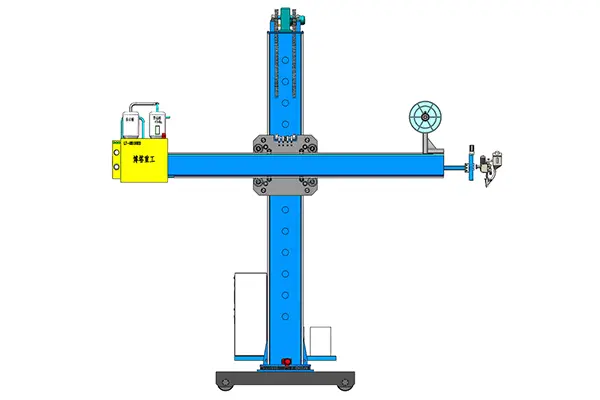

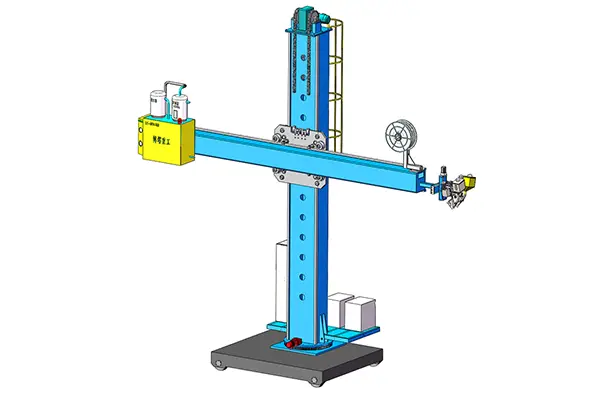

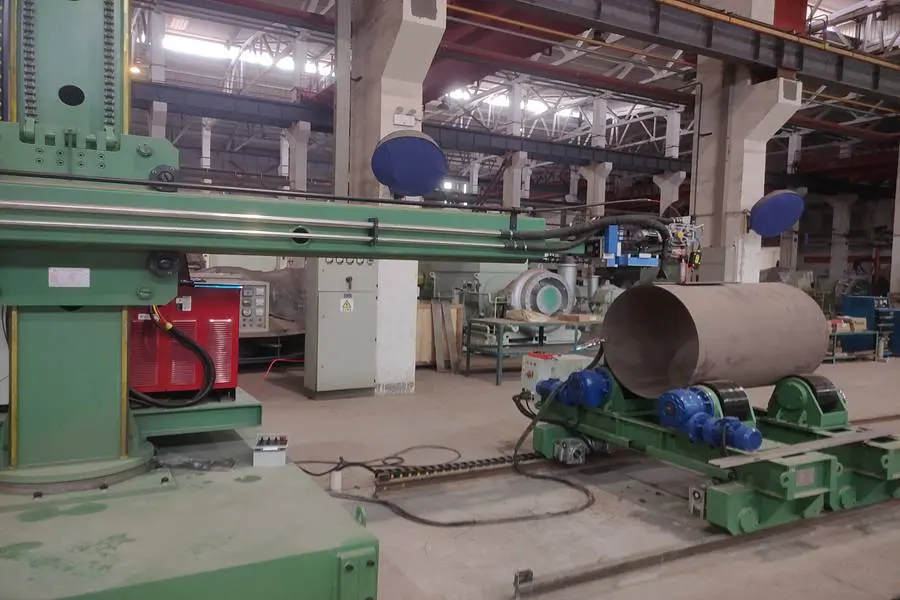

The heavy-duty welding manipulator is designed for automated welding of large and heavy workpieces, widely used in industries such as wind towers, boilers, pressure vessels, and large storage tanks. It features a robust structure with high load capacity, suitable for long-term, continuous, and high-intensity welding operations. When paired with welding rotators, positioners, and SAW systems, it delivers high-quality automated welding, making it ideal for heavy industry applications where stability and efficiency are essential.

Features

| Model Parameter | BCZZ4*4 | BCZZ5*5 | BCZZ6*6 | BCZZ7*7—8*8 | BCZZ9*9—12*12 |

|---|---|---|---|---|---|

| Effective lifing range(mm) | 4000 | 5000 | 6000 | 7000—8000 | 9000-12000 |

| Effective retracting range(mm) | 4000 | 5000 | 6000 | 7000—8000 | 9000-12000 |

| Lifting speed(mm/min) | 1000 | 1000 | 1000 | 1000 | 1000 |

| Retracting speed(mm/min) | 100-1000 | 100-1000 | 100-1000 | 100-1000 | 100-1000 |

| Retracting speed(mm/min) | 900-1200 | 900-1200 | 900-1200 | 900-1200 | 900-1200 |

| Max permissible load at boom end (kg) | 200-300 | 200-300 | 200-300 | 200-300 | 200-300 |

| Column rotation Angle(°) | ±180° | ±180° | ±180° | ±180° | ±180° |

| Column rotation Speed(rpm) | 0.36rpm/ Manual otaion | 0.36rpm/ Manual otaion | 0.36rpm/ Manual otaion | 0.36rpm/ Manual otaion | 0.36rpm/ Manual otaion |

| Trolley Traveling Speed (mm/min) | 2000 | 2000 | 2000 | 2000 | 2000 |

| Trolley rail inner span (mm) | 2000-3000 | 2000-3000 | 2000-3000 | 2000-3000 | 2000-3000 |

Designed for Intelligent Welding

Vibration-Free SAW Performance

Submerged Arc Welding (SAW) demands absolute stability. Our heavy-duty box construction ensures zero vibration at full boom extension, creating a stable platform for the weld pool. This rigidity is critical for achieving deep penetration and X-ray quality welds on thick-walled pressure vessels.

Designed for Intelligent Welding

High-Capacity Boom Structure

Unlike lightweight models, our heavy-duty manipulators are engineered with minimal deflection capability to carry substantial payloads. They easily support heavy SAW wire feeders, hoppers, and flux recovery systems at the boom tip without sagging, ensuring the nozzle position remains precise.

Optional Accessories

Global Client Showcase

In multiple countries and regions around the world, we provide high-quality welding equipment and have successfully offered customized solutions to clients across various industries. Our customers span multiple sectors, including automotive manufacturing, construction, shipbuilding, aerospace, and more.

Trusted by Global Clients

Request a Quote Now

By submitting a simple quote request, you can quickly receive purchasing recommendations and pricing tailored to your project.