Overview

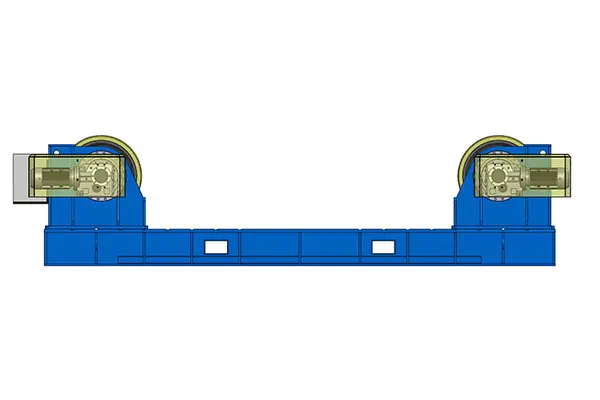

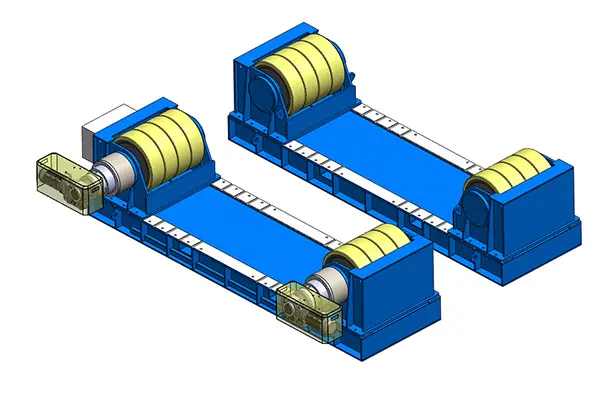

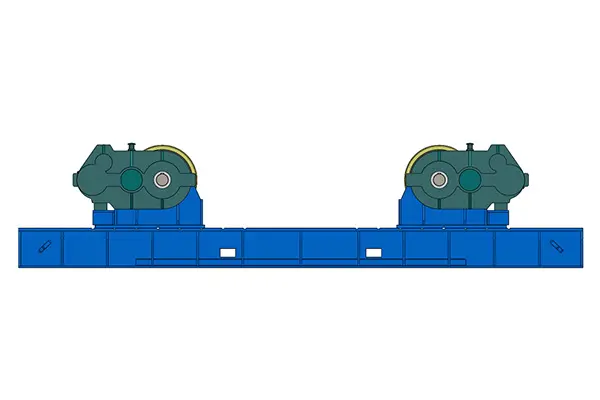

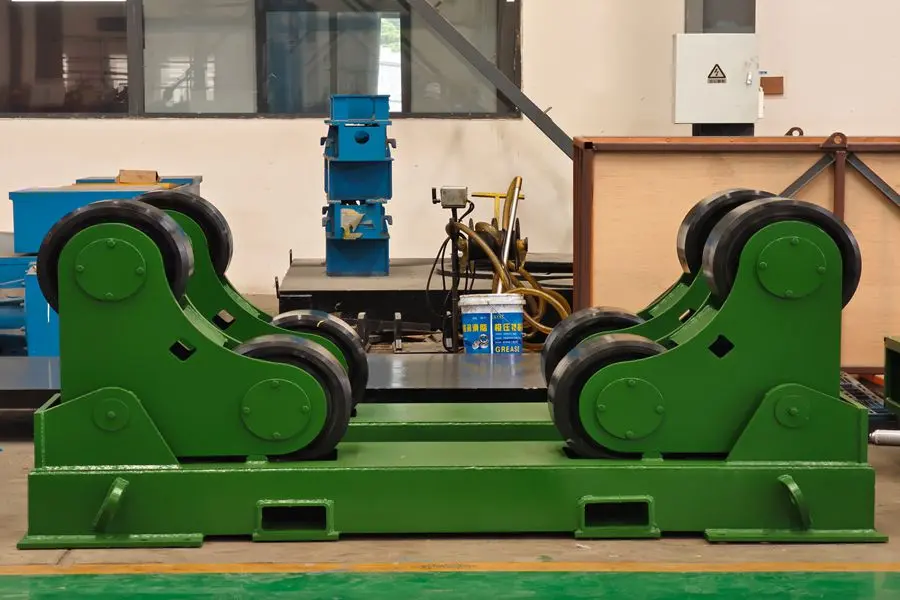

This series utilizes pre-designed bolt holes or lead screw adjustments to regulate the center distance of the roller group,accommodating variations in the diameter of the workpiece. The polyurethane covered rollers boast high load-bearing capacity and strong driving capability. An imported variable frequency drive inverter enables seamless speed adjustment, offering a wide range of speed control with high precision and substantial starting torque.

Features

| Model | Load(T) | Wheel Dia(mm) | Wheel Width(mm) | Workpiece Diameter(mm) |

|---|---|---|---|---|

| BKT - 1(Lead Screw) | 1 | 200 | 50 | 150-1500 |

| BKT - 3(Lead Screw) | 3 | 200 | 100 | 200-2000 |

| BKT - 5(Lead Screw) | 5 | 250 | 120 | 200-2500 |

| BKT-10 | 10 | 300 | 120 | 300-3000 |

| BKT-20 | 20 | 300 | 200 | 300-3500 |

| BKT-30 | 30 | 350 | 220 | 300-4000 |

| BKT-40 | 40 | 425 | 220 | 300-4500 |

| BKT-50 | 50 | 425 | 220 | 300-4500 |

| BKT-60 | 60 | 450 | 220 | 600-5000 |

| BKT-80 | 80 | 500 | 300 | 800-5500 |

| BKT-100 | 100 | 500 | 400 | 1000-6000 |

| BKT-120 | 120 | 500 | 400 | 1000-6500 |

| BKT-150 | 150 | 550 | 500 | 1100-7000 |

| BKT-200 | 200 | 600 | 500 | 1200-8000 |

Designed for Intelligent Welding

Customized Grip Angle

For extremely heavy or eccentric workpieces, traction is critical. The adjustable bolt system allows you to manually set the rollers to the optimum included angle, ensuring maximum friction grip and torque transmission to prevent slippage during heavy-duty welding.

Designed for Intelligent Welding

Robust Solution for Dedicated Lines

If your production line handles a consistent range of diameters, the BKT series offers the most economical and rigid solution. Its simple, rugged structure minimizes maintenance points while providing the brute strength needed for high-tonnage wind tower or pressure vessel fabrication.

Global Client Showcase

In multiple countries and regions around the world, we provide high-quality welding equipment and have successfully offered customized solutions to clients across various industries. Our customers span multiple sectors, including automotive manufacturing, construction, shipbuilding, aerospace, and more.

Trusted by Global Clients

Request a Quote Now

By submitting a simple quote request, you can quickly receive purchasing recommendations and pricing tailored to your project.