Welding, Smarter Than Ever

Delivering Efficient Welding Solutions for Smarter Manufacturing

Designed for Intelligent Welding

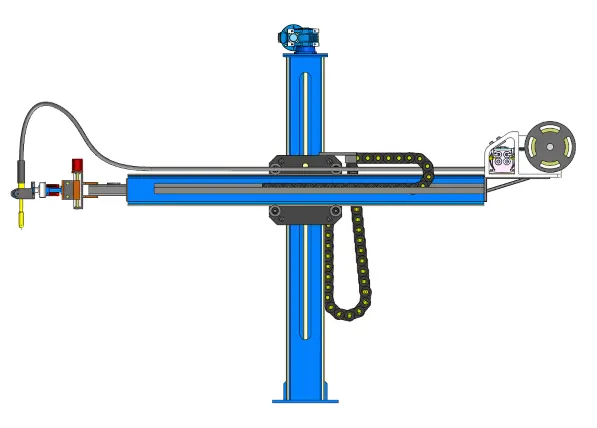

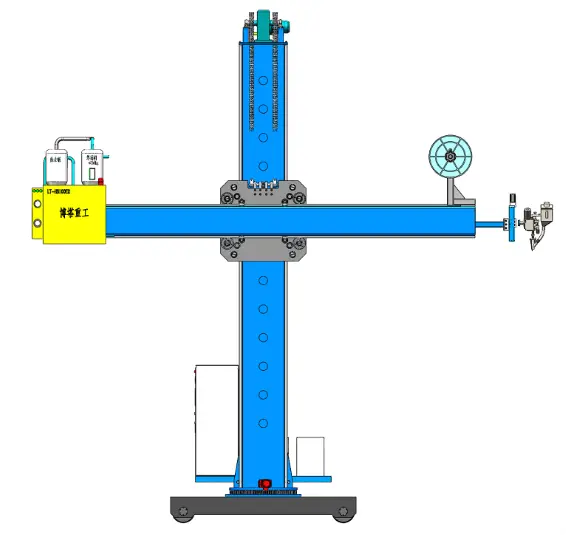

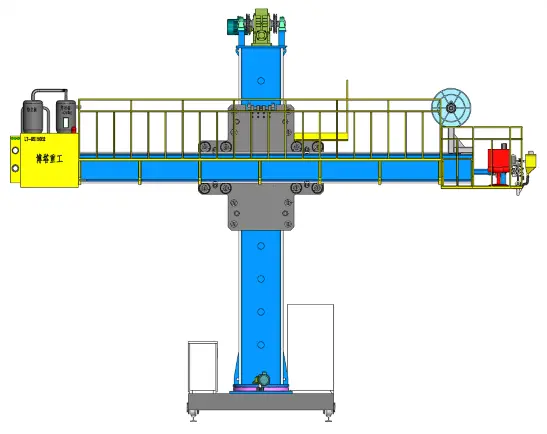

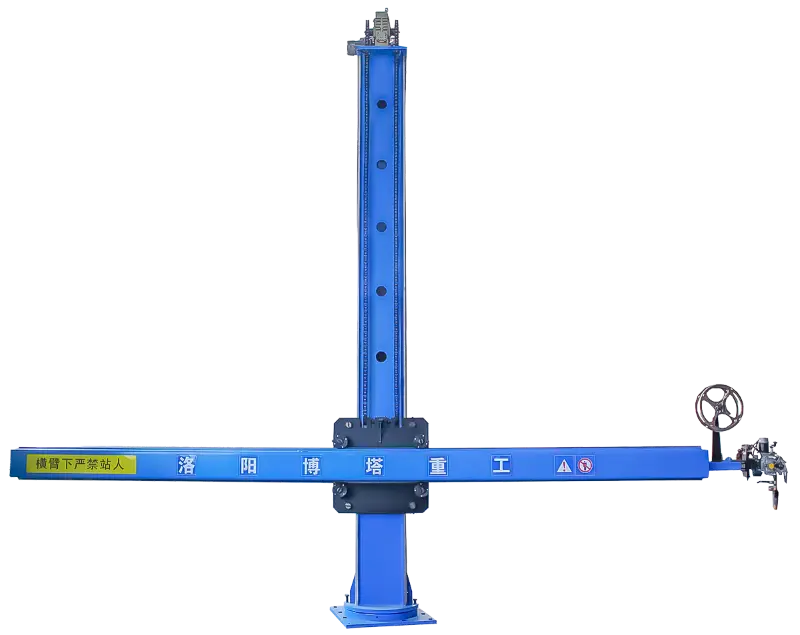

Welding Column Boom

The welding column boom enables automated vertical and horizontal movement of the welding head, often used with rotators and positioners for complete welding automation. With a stable structure and customizable stroke, it is ideal for longitudinal and circumferential seam welding of pipes, tanks, and structural components.

Designed for Intelligent Welding

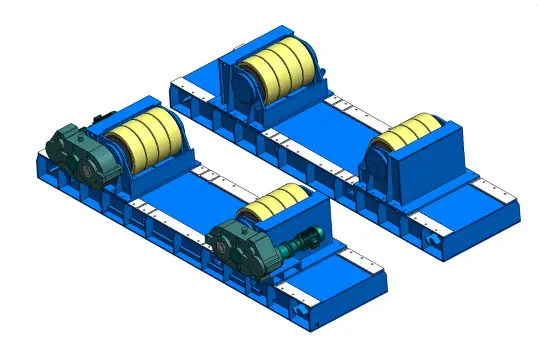

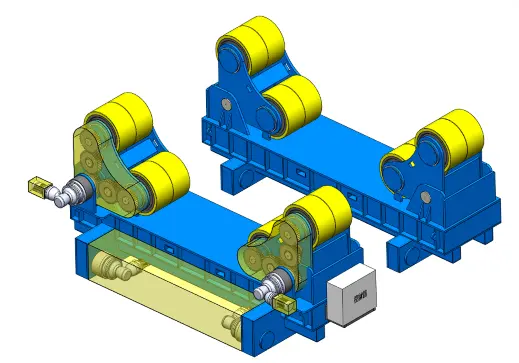

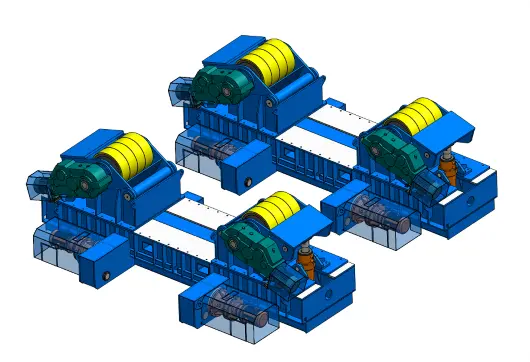

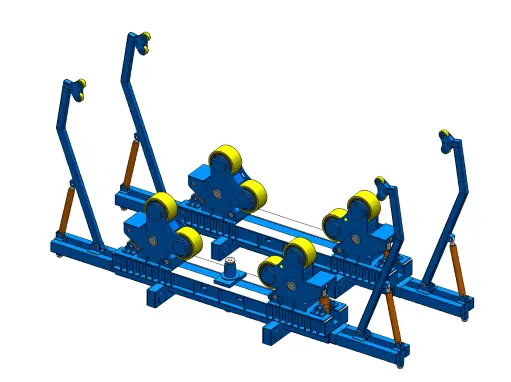

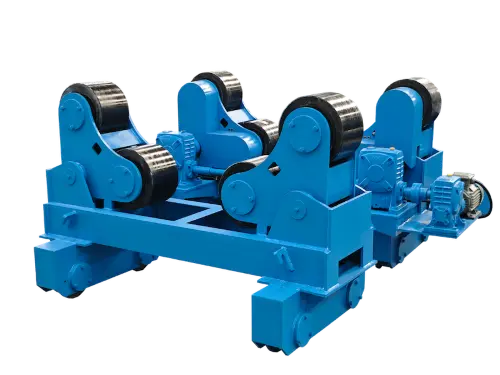

Welding Rotator

Welding rotators are widely used for automatic welding and rotation of cylindrical workpieces such as pressure vessels, pipes, and tanks. Available in hydraulic, self-aligning, and conventional adjustable types to meet different size and application needs, ensuring higher efficiency and welding precision.

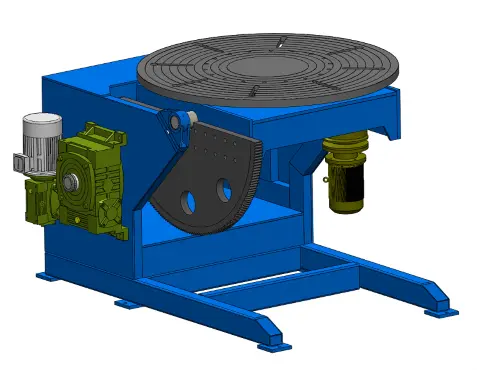

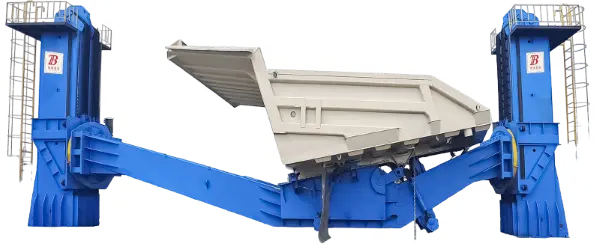

Designed for Intelligent Welding

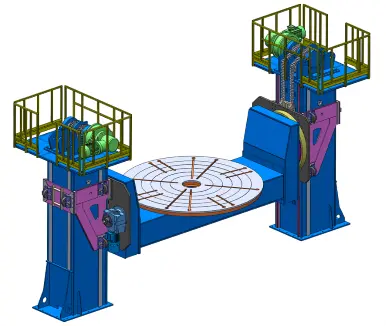

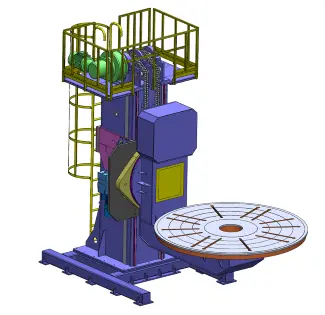

Welding Positioners

The welding positioner enables precise rotation and tilting of workpieces, allowing welding at optimal angles to improve efficiency and weld quality. Ideal for flanges, tube sheets, frames, and more, and can be integrated with column booms and rotators for automated welding systems.

Our Story, Your Solution

About Us

Bota Heavy Industry is building intelligent welding and cutting solutions for manufacturers worldwide. With CE certification and a 50,000㎡ facility, our equipment serves industries like wind power, bridges, and towers across Europe, Southeast Asia, and beyond. Whether standard or customized, our mission is to make your production smarter and more efficient.